Tips and tricks for more sustainability in the laboratory

Pipetting liquids in the microliter and milliliter range is one of the most common tasks in the laboratory. While the consumption of resources may seem small compared to operating large equipment such as freezers, there are ways to be more sustainable when pipetting. We have put together some practical tips for environmentally conscious laboratory professionals to minimize the environmental impact of their daily work.

Reduce – Reuse – Recycle

The measures fall into three areas:

+ Reducing emissions and waste

+ Extend the life of equipment

+ Reuse products and raw materials

Reduce emissions and waste

Consumables such as pipette tips have a significant environmental impact. Their production requires significant amounts of electrical energy, and after use, the tips must be disposed of and the used boxes must be reused, recycled, or disposed of.

Reducing emissions

BRAND produces in Germany with 100% green electricity from certified hydroelectric power plants and self-generated electricity as a by-product of our heat generation in an efficient combined heat and power plant. This allows us to significantly reduce greenhouse gas emissions. See our environmental goals for more information.

Reduce waste

BRAND manufactures its tips in an extra thin-walled design, which reduces the amount of plastic used in the production process. And with the TipRack refill system, the amount of waste is reduced by more than 20% compared to the TipBox.

Watch our video to see how the TipRack refill system saves material:

Extend the life of your instruments

Extending the life of a product conserves raw materials and energy, and the most environmentally friendly product is the one that never needs to be manufactured in the first place. Both users and manufacturers can do a lot to ensure that laboratory equipment lasts, even when high standards of precision and reliability are required.

High quality materials and durable construction

BRAND uses only the highest quality materials for pipettes, such as the pistons. We use either corrosion resistant metal or a high performance plastic with very high temperature and chemical resistance. The material used is resistant to almost all organic and inorganic chemicals and has excellent sliding properties with very good abrasion and wear resistance.

Due to the use of such materials, BRAND pipettes can often be used in the laboratory for many years. Actual service life depends on factors such as media, handling and maintenance. Under standardized test conditions, a Transferpette® S can perform 500,000 strokes and 200,000 tip ejections without compromising accuracy or function – a true "long runner" in the laboratory. Regular cleaning and maintenance can significantly extend its life.

In addition, the entire unit can be autoclaved directly at 121°C.

Easy maintenance and adjustment

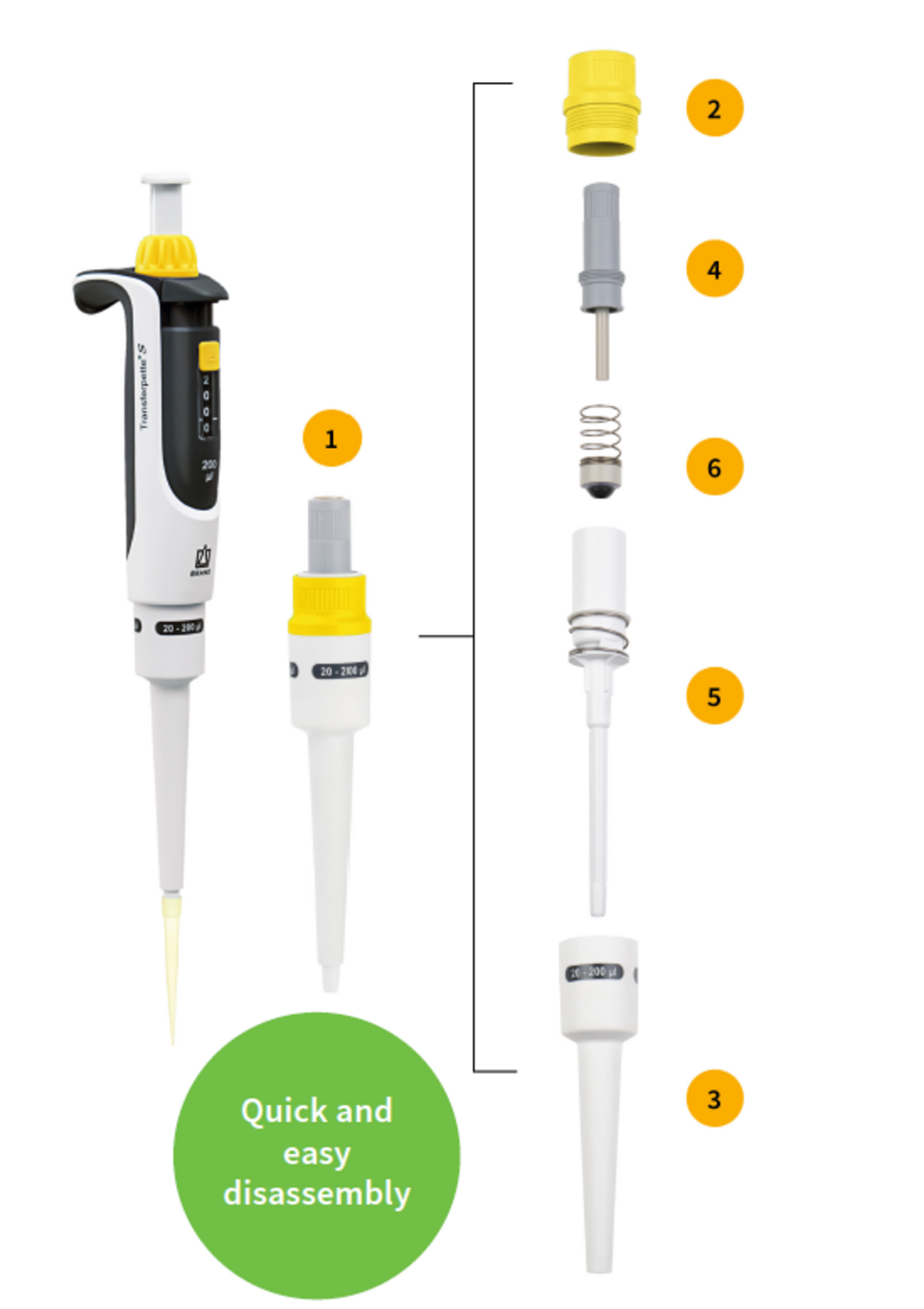

Regular maintenance and care to ensure a long service life is easy and time-saving with the Transferpette® S.

The seals, shaft and piston of the Transferpette® S can be easily checked for functionality and replaced if necessary. This eliminates or minimizes the need to send the Transferpette® S to a calibration laboratory, thereby reducing emissions from transportation.

The ejector and shaft of the single-channel Transferpette® S models can be removed and cleaned in seconds. Multi-channel instruments feature a design that allows the individual shafts to be unscrewed for easy cleaning and replacement. No special tools are required and the units are immediately ready for use.

BRAND offers inexpensive replacement parts for these assemblies that customers can install themselves. The right accessories and spare parts for an individual instrument can be found and ordered quickly and easily by scanning the QR code on the pipette.

BRAND pipettes also make it easy to perform the regular calibrations required to monitor test equipment. If a readjustment is necessary, it can be performed quickly and easily using the EasyCalibration technology. EasyCalibration can also be used to adjust the instrument to solutions of different densities and viscosities or to specially shaped pipette tips.

Reuse and recycling of products and raw materials

While the recycling of used tips is limited today due to possible contamination, there are other ways to reuse or recycle products and raw materials.

The sturdy TipBoxes can be refilled with tips and in many cases autoclaved. Made from 100% pure PP, they can be completely recycled at the end of their useful life.

Product packaging can also contribute to sustainability. BRAND already uses cardboard packaging with a recycled content of around 90% for many of its product packages.

For some applications, switching to reusable glass pipettes instead of disposable plastic tips is also an option. BRAND offers graduated, volumetric and serological pipettes for this purpose. Depending on the application and cleaning cycles, glass pipettes can be used many hundreds of times.

BRAND also offers various pipetting aids for this purpose, such as the accu-jet® S, which impresses with its sustainability in production and service life.

Products and More Information

BRAND products are listed by many distributors in their green product programs. For more information, contact your local distributor.