Pipetting robot

A new concept in lab automation

Automation of routine pipetting tasks

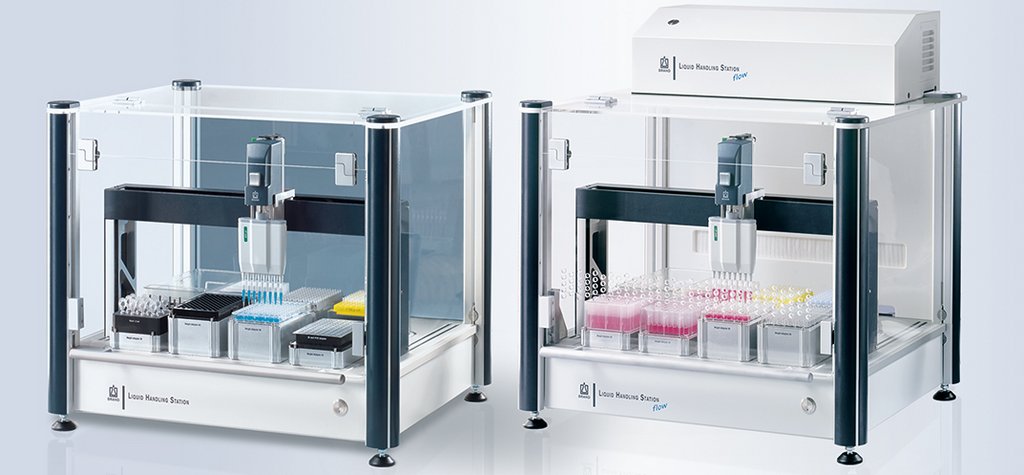

The new Liquid Handling Station (LHS) pipetting robot from BRAND is your entry point into laboratory automation. With an excellent price/performance ratio and straightforward operation, the system is economical for low and medium throughput labs. Typical applications include:

Enzyme assays

Enzyme assays

SIMPLE, EASY, and EFFICIENT

Liquid automation systems

Find out how simple automated pipetting can be with the intuitive BRAND software. Set up your own, customized methods in minutes. The procedure is as simple as preparing for manual pipetting. Instead of using predefined protocols, you work with your own pipetting procedures that can be saved for further use. Unique and convenient features save time in programming and method execution.

For example:

- the simulation mode lets you verify and optimize your method

- email notifications inform you of manual interventions and protocol progress

- and liquid ends can be changed without tools

Outstanding in every detail

Benefits of the pipetting robot

The Liquid Handling Station provides maximum flexibility for small and medium sample throughput and varied pipetting tasks. It closes the gap between electronic pipettes and large, expensive equipment. Seven ANSI / SLAS formatted workplaces can be freely assigned, including PCR tubes and strips, microcentrifuge tubes, reservoirs, and 96- or 384-well plates. Liquid ends are available in three single-channel sizes and two 8-channel sizes. The Liquid Handling Station's compact design and space-saving front door make it an ideal fit where benchtop space is limited.

Liquid Handling Station flow

Benchtop Cleanroom

The Liquid Handling Station flow is BRAND®’s pipetting robot for applications where samples must be protected from particles and microorganisms. Its brand new FlowBox directs the filtered air flow in laminar, horizontal layers across the consumables, such as plates. With the door closed, the air volume inside the cabinet is replaced 260 times per hour, and exits through openings in the front door.

Downloads

Qualify and test - free of charge

The BRAND Method Check

Wondering whether automating your method makes sense? Request BRAND’s free Method Check for laboratories! Experts from BRAND will analyze your pipetting tasks and give you specific recommendations on how to automate your applications. Then take two full weeks to test the method right in your own lab using the Liquid Handling Station – free of charge!

Your Method

- PCR or qPCR

- ELISA

- Reformatting and replicating plates

- Preparing assay-ready plates

- Cherry picking

- Enzyme assays

- Other methods

Method Check

- Analyze your laboratory’s pipetting tasks

- Define settings, e.g. fluid properties (liquid types)

- Specific recommendations for automating your methods

Validation

- Use a BRAND Liquid Handling Station free of charge for two weeks

- Free BRAND consumables such as tips or plates for your in-lab demonstration

- Benefit from BRAND on-site training for the design and implementation of your pipetting methods

Liquid Handling Station Custom Labware Order

If your labware is not included in our labware database, you can order a labware file for the required labware (Cat-No. 998160) which can be imported into the software.

- Please send the labware (+ form) to BRAND

- A labware file will be created and then can be imported into the software.

Depending on the labware a custom adapter/rack is required and can be ordered as well (Cat-No. 998134 + 998158).

Expert advice available!

We are your automated liquid handling professionals

Just call us or fill in the form below. We will gladly show you how the Liquid Handling Station can streamline your pipetting work. Make an appointment for a free, on-site method check today!

United States

BrandTech Scientific Inc.

Tel.: +1 860 767 2562

In USA, call toll-free: 888 522 2726

info@brandtech.com

United Kingdom

Tel.: +44 7917 861 821

john.mitchell@brand.de

Benelux

Tel.: +32 470045870

Tel.: +31 625324416

carlos.naipal@brand.de

China

BRAND (Shanghai) Trading Co., Ltd.

Tel: +86 21 6422 2318

info@brand.com.cn

India

BRAND Scientific Equipment Pvt. Ltd.

Tel: +91 22 42957790

info@brand.co.in

Malaysia

Interscience Sdn Bhd

Tel.: +60 3 5740 9888

info@its-interscience.com

Singapore

IST Science & Medical Pte Ltd

Tel.: +65 6309 3202

info@its-interscience.com

Save precious time with liquid handling automation

The Liquid Handling Station from BRAND: fast, quiet, and reliable.

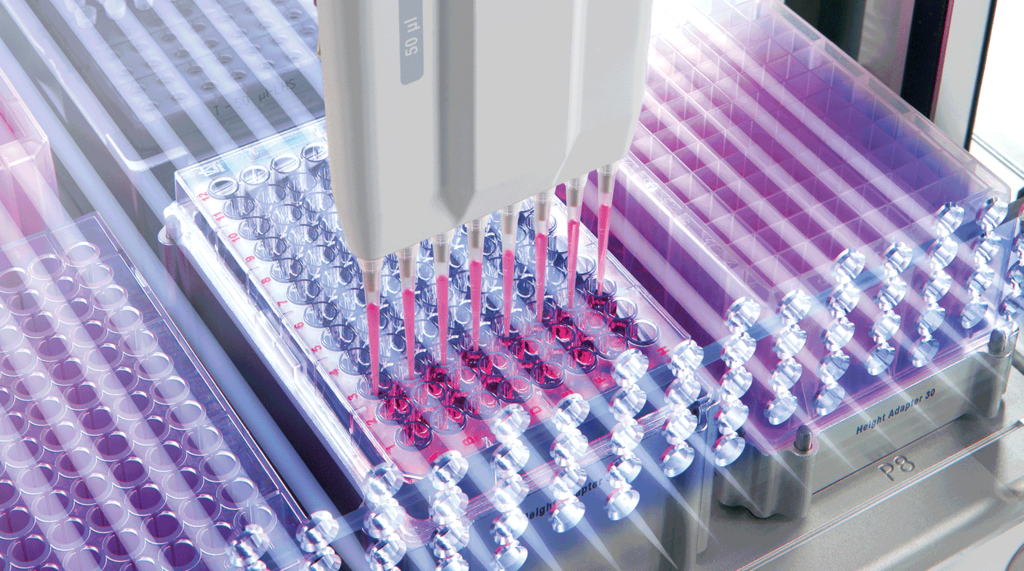

The speeds and the particularly dynamic movements of the axis system are designed to permit rapid, exact pipetting while simultaneously minimizing the risk of contamination due to loss of liquid drops during movement. Adapters bring the plates/racks used to a single height, reducing unnecessary vertical move - ments. That saves time during pipetting!

Simply uncomplicated!

The Liquid Handling Station from BRAND combines 45 years of experience in the area of manual Liquid Handling with over 30 years in the manufacture of high-precision disposable items. The pipette system works on the same air-interface principle as the piston-operated pipettes widely used in laboratories, and is designed for medium sample throughput. It takes care of simple, monotonous (and frequently error-prone) routine tasks as well as complex pipetting tasks, such as PCR, qPCR or cherry picking, working through them efficiently.

Maximize product protection

A microprocessor-controlled horizontal, laminar air flow safely covers the entire working area. The air drawn in from the environment passes through an H14 HEPA filter (99.995% efficiency). The filtered air is then directed across the working area in a laminar flow pattern.